Fitting

Clean the contact surfaces between wheel and hub.

Put on the wheel. Tighten the wheel nuts thoroughly.

Lower the car so that the wheels cannot rotate.

Tighten the wheel nuts crosswise. It is important that the wheel nuts are tightened with the correct tightening torque. Check the torque with a torque wrench.

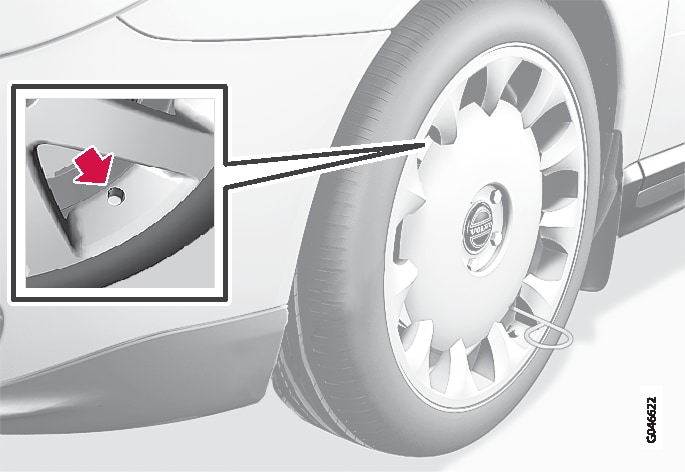

Refit any full wheel covers.

Note

The wheel cover outlet for the valve must be positioned over the valve on the wheel rim during fitting.

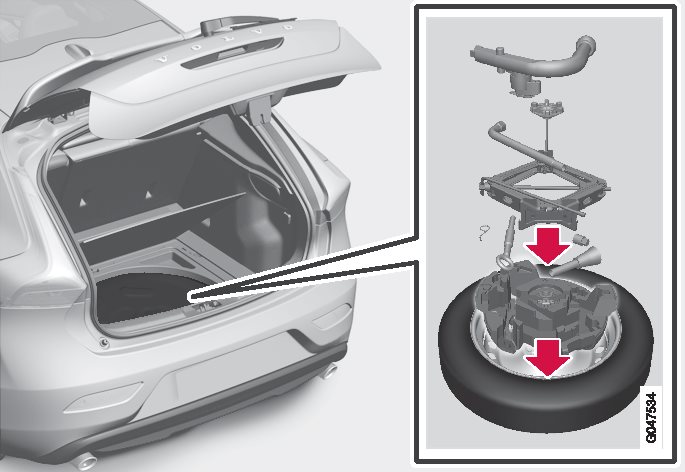

Putting back the jack* and tools

The tools and jack must be returned to their correct places in the foam block after use.

Unscrew the towing eye from the wheel bolt wrench.

Put any tools used back in their individual compartments in the foam block in the following order:

- towing eye/funnel/torx wrench/socket for locking wheel nuts/tool for wheel covers

- jack (must be cranked to the correct height so that it fits into the foam block's compartment, the handle above the foot and down in the groove in the foam block)

- socket wrench (above the jack).

If the spare wheel has been used, then the punctured wheel can be placed in the plastic bag contained in the package with the gloves. Place the foam block back in the storage compartment and tighten the mounting screw to the floor of the storage compartment.

If the spare wheel has not been used, place the foam block in the spare wheel and place the spare wheel back in the storage compartment. Tighten the attaching screw to the floor of the storage compartment.

Return the detachable towbar.

Note

- After a tyre has been inflated, always refit the dust cap in order to avoid damage to the valve from gravel, dirt, etc.

- Only use plastic dust caps. Metal dust caps can rust and become difficult to unscrew.

Important

The tools and jack* must be stored in the intended location in the car's cargo area when not in use.