Using the emergency puncture repair kit

Overview

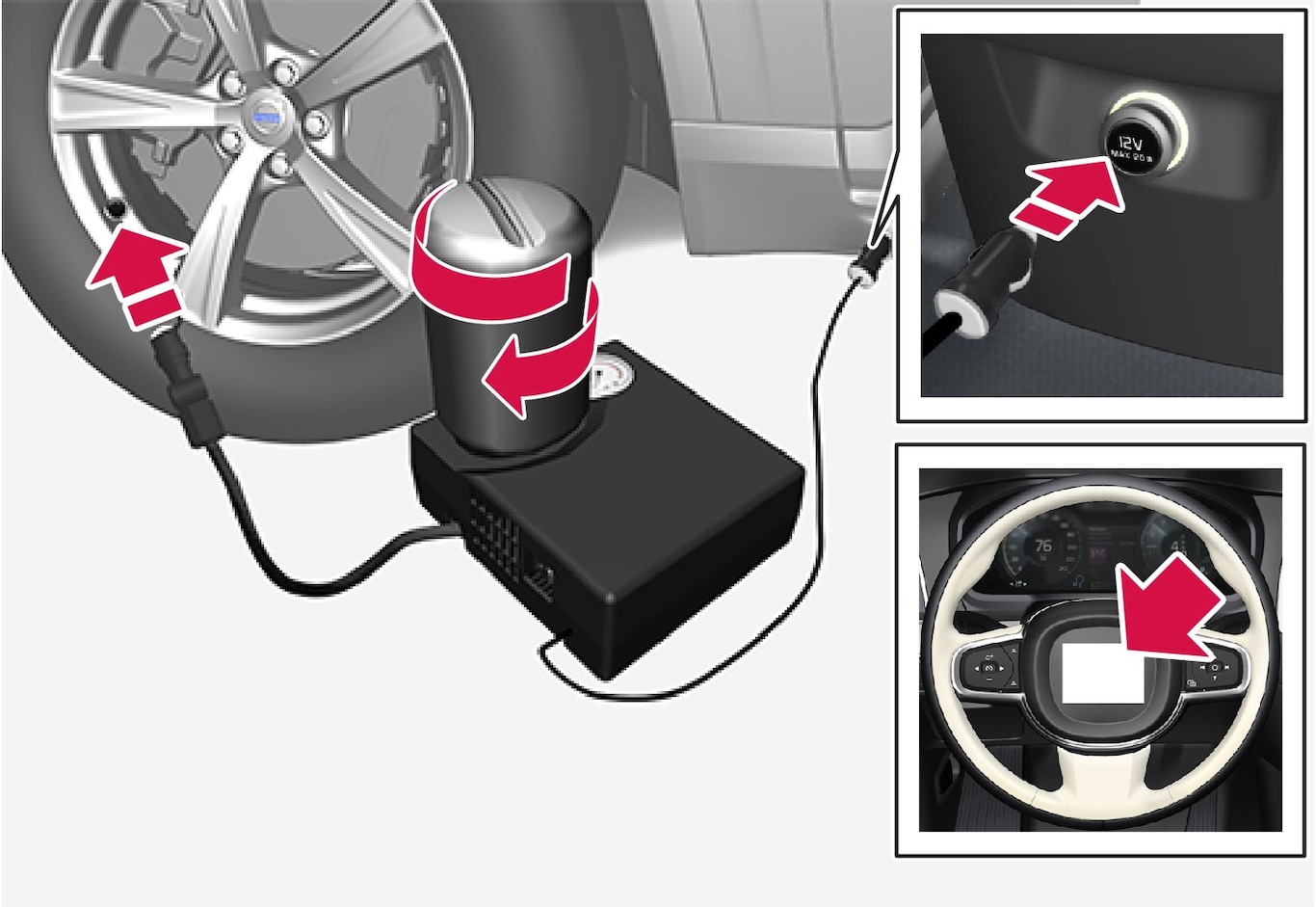

Electrical cable

Electrical cable Air hose

Air hose Pressure reducing valve

Pressure reducing valve Protective cap

Protective cap Bottle holder (orange cap)

Bottle holder (orange cap) Pressure gauge

Pressure gauge Label, maximum permitted speed

Label, maximum permitted speed Sealing fluid bottle

Sealing fluid bottle Switch

Switch

Connecting

Set up the warning triangle and activate the hazard warning lights if a tyre is being sealed in a trafficked location.

If the puncture was caused by a nail or similar, allow this to remain in the tyre. It helps to seal the hole.

Note

Warning

Warning

Unscrew the tyre's dust cap.

Check that the pressure reducing valve on the air hose is fully screwed on, and screw in the air hose's valve connection to the bottom of the tyre valve's thread.

Note

Warning

Warning

Note

Important

Warning

Note

Warning

Follow-up inspection

Connect the air hose on the tyre valve and screw in the valve connection to the bottom of the tyre valve's thread. The compressor must be switched off.

Read the tyre pressure on the pressure gauge.

- If it is below 1.3 bar then the tyre is insufficiently sealed. The journey should not be continued. Contact a tyre centre.

- If the tyre pressure is higher than 1.3 bar, the tyre must be inflated to the pressure specified in accordance with the tyre pressure label on the driver side door pillar (1 bar = 100 kPa). Release air using the pressure reducing valve if the tyre pressure is too high.

If the tyre needs to be inflated:

- Connect the electrical cable to the closest 12 V socket and start the car.

- Start the compressor and inflate the tyre to the pressure specified in accordance with the tyre pressure label.

- Switch off the compressor.

Remove the tyre sealing equipment, fit the protective cap on the air hose and fold the hose in the box.

Place TMK in the cargo area.

Warning

Note

- After a tyre has been inflated, always refit the dust cap in order to avoid damage to the valve from gravel, dirt, etc.

- Only use plastic dust caps. Metal dust caps can rust and become difficult to unscrew.

Note

Warning

Volvo recommends that the car is driven to the nearest authorised Volvo workshop for the replacement/repair of the damaged tyre. Advise the workshop that the tyre contains sealing fluid.