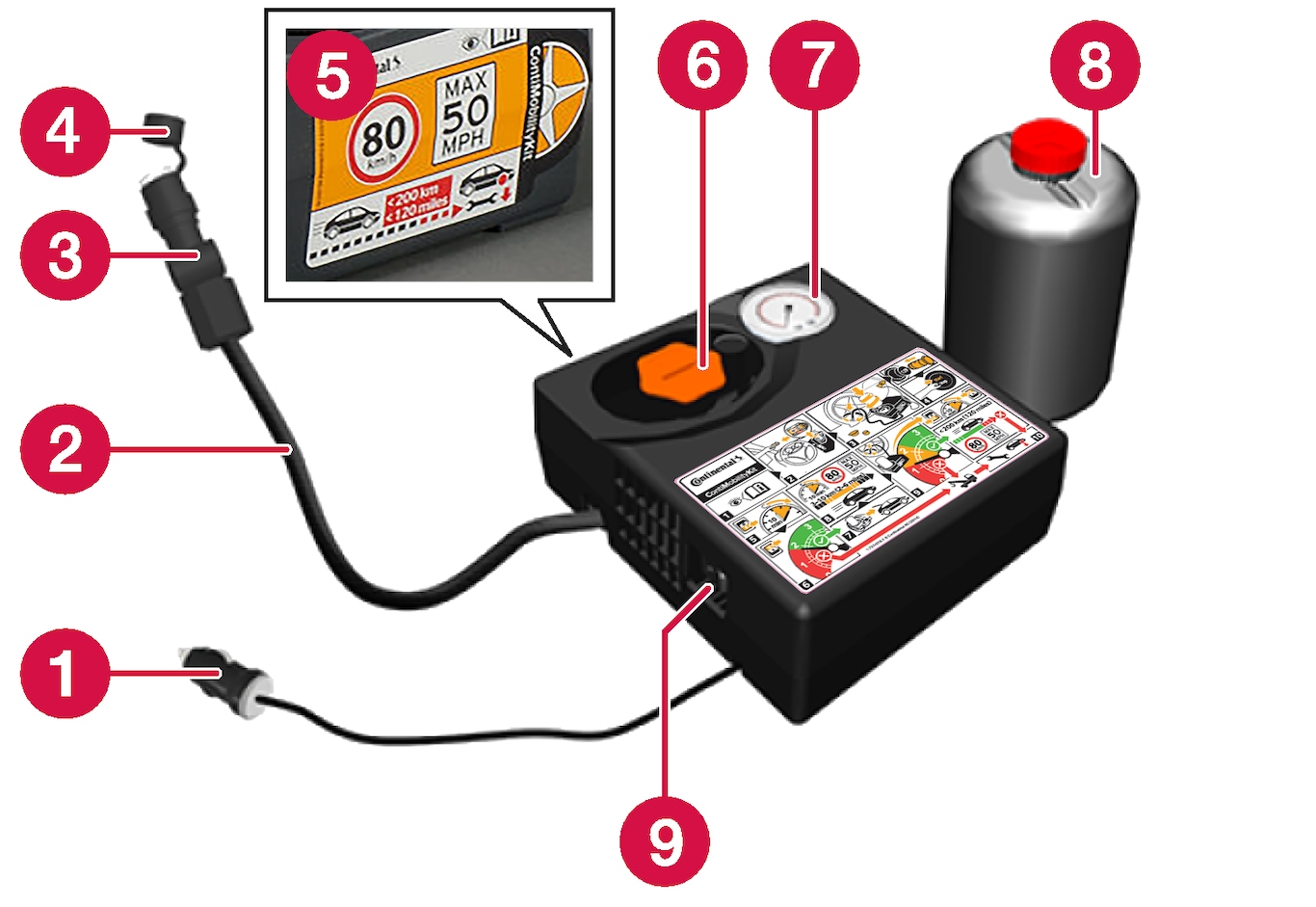

Overview

Electrical cable

Electrical cable Air hose

Air hose Pressure reducing valve

Pressure reducing valve Protective cap

Protective cap Label, maximum permitted speed

Label, maximum permitted speed Bottle holder (orange cap)

Bottle holder (orange cap) Pressure gauge

Pressure gauge Sealing fluid bottle

Sealing fluid bottle Switch

Switch

Connecting

Note

Warning

- The sealing fluid bottle contains 1) rubber latex, natural and 2) ethanediol. These substances are harmful if swallowed.

- The contents of this bottle may cause allergic skin reactions or otherwise be potentially harmful to the respiratory tract, the skin, the central nervous system, and the eyes.

- Store out of the reach of children.

- Harmful if ingested.

- Avoid prolonged or repeated contact with the skin. If sealing fluid has come into contact with your clothes, remove them.

- Wash thoroughly after handling.

- Skin: Wash affected areas of skin with soap and water. Get medical attention if symptoms occur.

- Eyes: Flush with plenty of water for least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical attention if symptoms occur.

- Inhalation: Move the exposed person to fresh air. If irritation persists, get medical attention.

- Ingestion: Do NOT induce vomiting unless directed to do so by medical personnel. Get medical attention.

- Disposal: Dispose of this material and its container at a hazardous or special waste collection point.

Warning

- Do not remove the bottle when the puncture repair kit is being used.

- Do not remove the air hose when the puncture repair kit is being used.

Set up the warning triangle and activate the hazard warning lights if a tyre is being sealed in a trafficked location.

If the puncture was caused by a nail or similar, allow this to remain in the tyre. It helps to seal the hole.

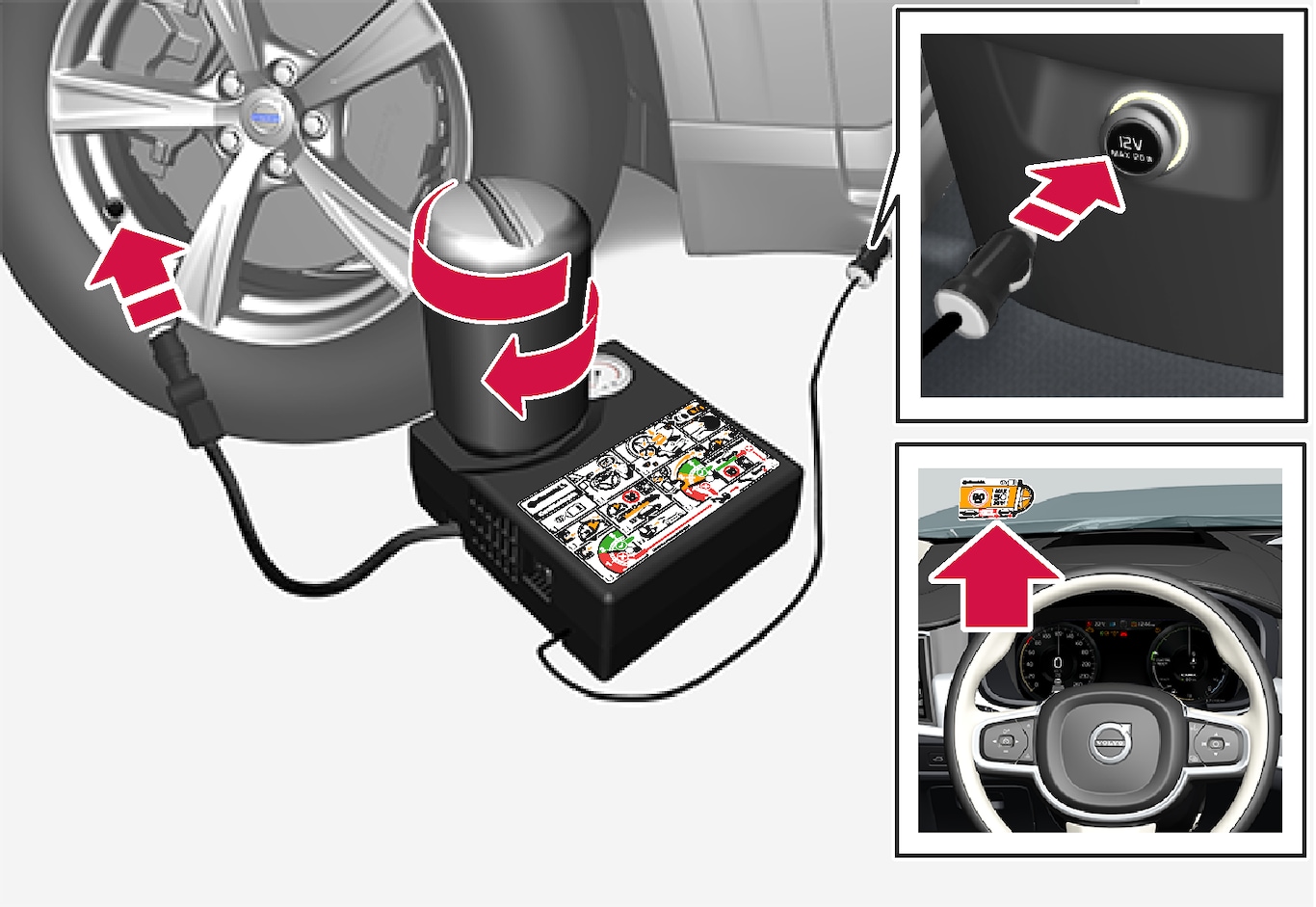

Screw in the bottle to the bottom of the bottle holder.

The bottle and the bottle holder are equipped with a reverse catch to prevent sealant leakage. When the bottle is screwed in it cannot be unscrewed from the bottle holder again. Bottle removal must be performed at a workshop, Volvo recommends an authorised Volvo workshop.

Warning

Unscrew the tyre's dust cap and screw in the air hose's valve connection to the bottom of the thread on the tyre's air valve.

Check that the pressure reducing valve on the air hose is fully screwed in.

Note

Warning

Warning

Note

Important

Warning

Warning

Note

Warning

Follow-up inspection

Connect the air hose on the tyre valve and screw in the valve connection to the bottom of the tyre valve's thread. The compressor must be switched off.

Read the tyre pressure on the pressure gauge.

- If it is below 1.3 bar (19 psi) then the tyre is insufficiently sealed. The journey should not be continued. Call roadside assistance for recovery.

- If the tyre pressure is higher than 1.3 bar (19 psi), the tyre must be inflated to the pressure specified in accordance with the tyre pressure label on the driver's side door pillar (1 bar = 100 kPa = 14.5 psi). Release air using the pressure reducing valve if the tyre pressure is too high.

Note

Warning

Volvo recommends that the car is driven to the nearest authorised Volvo workshop for the replacement/repair of the damaged tyre. Advise the workshop that the tyre contains sealing fluid.